Step‑by‑Step Guide to Sourcing Injection Molding in China

The important meeting has recently finished, your new product has been approved, the schedule is tight, and the budget is… well, let’s just say it’s tight.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

Of course, you acknowledge. It makes sense on paper. Savings can be substantial. However, your brain is racing with concerns. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

However, here’s the reality. Procuring plastic mold company needn’t be a roll of the dice. It’s simply another project with clear steps. And its outcome hinges on the approach you take. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Forget the horror stories. Let’s walk through a real-world playbook for getting it right.

Step One: Do Your Homework

Before searching suppliers or opening Alibaba, nail down your requirements. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You can’t expect a factory on the other side of the world to read your mind. It’s akin to asking someone to price-build “a structure” with no details. The responses you get will be all over the map, and none of them will be useful.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

What belongs in your RFQ?

First, your 3D CAD files. They’re essential. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Call out smooth surfaces or precision hole sizes in big, bold notation.

Next up, material. Don’t label it simply “Plastic.” Even “ABS” alone is too vague. Be explicit. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. Why be exact? Because resin grades number in the thousands. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

Lastly, add your business data. What is your Estimated Annual Usage (EAU)? A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Cavity count, tooling cost, and per-unit pricing depend on volume.

Finding the Right Supplier

Okay, your RFQ package is a work of art. who gets your RFQ? The web is vast but overwhelming. It’s easy to find a supplier; it’s hard to find a good one.

You’ll probably kick off on Alibaba or Made-in-China. They offer breadth but not depth. Treat them as initial research tools, not final solutions. Aim for a preliminary list of 10–15 potential partners.

Still, you must dig deeper. Consider using a sourcing agent. Yes, they take a cut. But a reputable agent brings pre-screened factories. They bridge language and cultural gaps. As a newcomer, this offers priceless security. It’s schedule protection.

Another classic method? Trade shows. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Nothing beats a face-to-face conversation. Hold samples, talk shop, and gauge professionalism firsthand. Also, leverage the tried-and-true referral network. Tap your professional contacts. A recommendation from a trusted peer is often worth its weight in gold.

Shortlisting Serious Suppliers

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. the quotes will start trickling in. Some will be shockingly low, others surprisingly high. Now, sift through and shortlist 2–3 reliable candidates.

What’s the method? It’s a bit of an art and a science.

Begin with responsiveness. Do they respond quickly and clearly? Is their English good enough for complex technical discussions? But here’s the real test: Are they asking you intelligent questions? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. You know they know their stuff. A “Sure, no issues” vendor often means trouble.

Then confirm their machinery specs. Request their machine list. Review examples of parts akin to your design. Don’t pick a micro-molding shop for large components.

Finally, inspect the factory. You can’t skip this. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s a tiny cost for huge peace of mind.

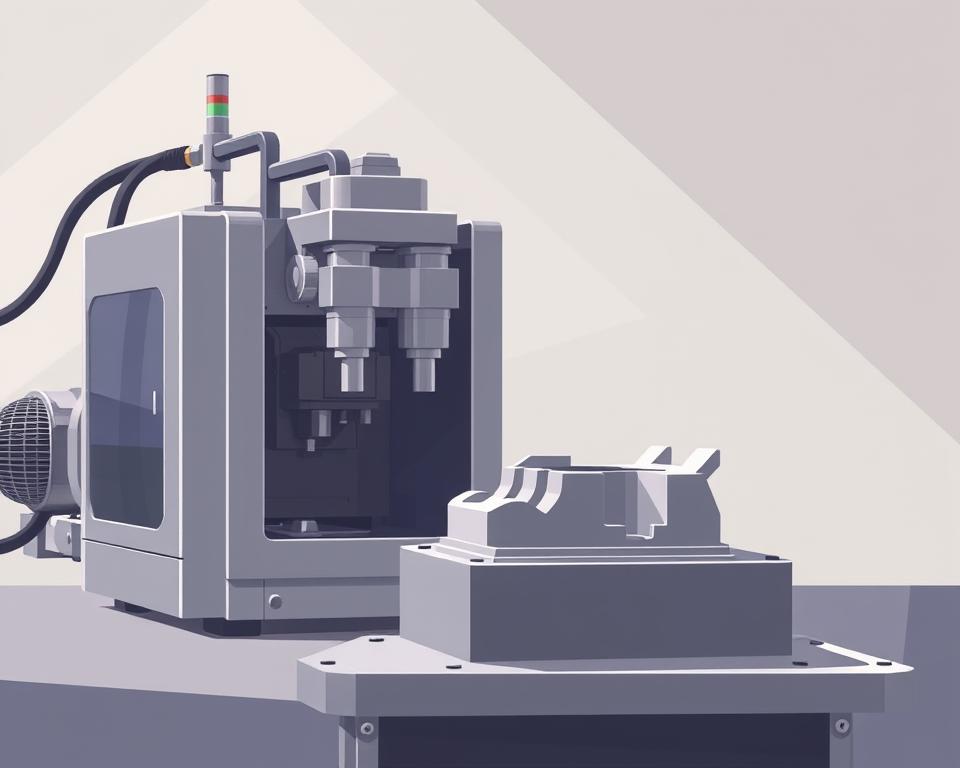

Transforming CAD into Real Parts

After picking your vendor, you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Then comes the real action.

Initially, expect a DFM report. DFM stands for Design for Manufacturability. It’s their professional review of your CAD. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. Comprehensive DFM equals a top-tier supplier. It’s a two-way partnership. Together, you tweak the design for best manufacturability.

With DFM sign-off, toolmaking begins. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These represent the first trial parts. It’s your first real test.

Be prepared: T1 samples are almost never perfect. This is normal! Look for small flaws, slight size errors, or surface marks. You critique, they refine, and T2 plastic mold in China parts arrive. You may repeat this cycle a few times. Build buffer time for sample iterations.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is your golden sample. You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How do you maintain consistency for part 10,000?

Put a strong QC process in place. Often, you hire a pre-shipment inspection service. Use a third-party inspector again. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This audit shields you from mass defects.

Don’t forget shipping details. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or EXW, shifting all transport to you? Your Incoterm selection drives landed expenses.

China sourcing is a long-haul effort. It relies on partnership-building. View them as allies, not vendors. Open dialogue, trust, and rigorous procedure deliver results. Certainly, it’s complex. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re ready.